Reduce LO & FO Consumption

The Marine Fluid Technology, Blending-on-Board lubrication system offers unparalleled lube oil and fuel oil consumption whilst simultaneously preventing cold corrosion & reducing maintenance costs.

Introducing the MFT Blending-on-Board technology.

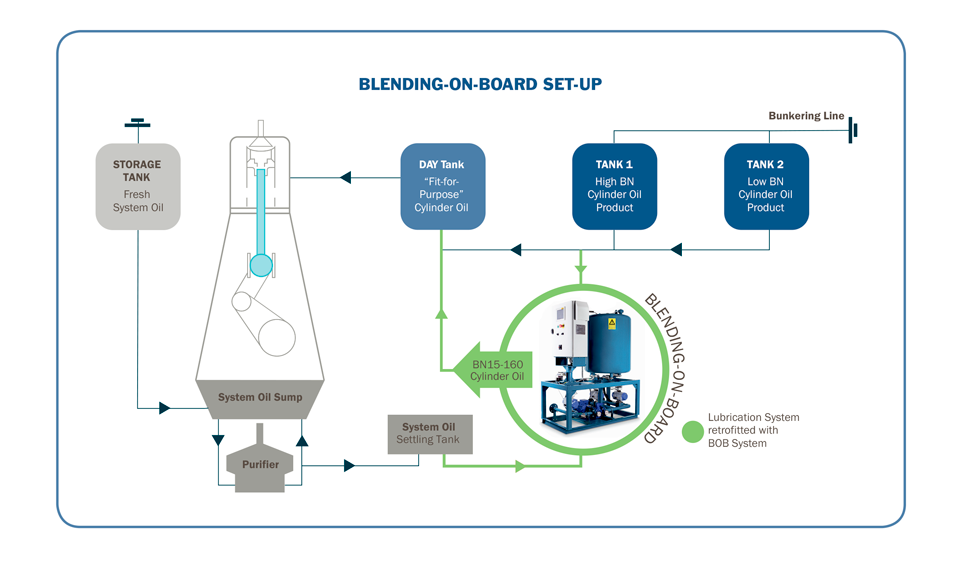

The SEA-Mate® Blending-on-Board System is an Innovative concept compared to conventional lubrication practices. The key difference being that BOB addresses both Crankcase and Cylinder lubrication needs at the same time, without the need to maintain and store multiple lubricant products onboard the vessel.

The SEA-Mate® BOB equipment puts control firmly back into the hands of the operator by providing greater flexibility in terms of their lubricant options to accommodate the many technical challenges faced onboard a modern vessel.

The equipment is designed to produce a finished Cylinder lubricant to a targeted specific Base Number at the flick of a switch. It really is as easy as that, as a lot of time and effort has been invested into making the equipment user friendly and simple to operate.

450+ Installs

1.5% Fuel Savings

40% LO Reduction

Key Benefits

Up to 1.5% Fuel Savings

Reduces Cold Corrosion, Liner & Piston wear

Up to 40% LO Reduction

Introducing the MFT Blending-on-Board System

The BoB system is run under semi-automatic operation, which gives you the opportunity to monitor the blender operation as you go along. The Programmable Logic Controller functions as an extra quality control that reacts to unforeseen events.

It is designed to plug right into the existing alarm system and will stop blending in case of an unlikely mechanical breakdown.

The control system contains all necessary security and safety features and comply with any Class Society requirement.

Easy to Install & Operate

The MFT BoB system is both Class and engine designer approved, and can be retrofitted within a regular port-stay. Operation is easy and BOB runs fully automatically.

WHITE PAPER

The Power of Steam

Download our exclusive "Power of Steam" white paper, which dives deep into the vast potential of utilising waste service steam onboard vessels to generate clean power. We even examine the ways in which owners and operators can implement small alterations to their existing steam consumers - such as LO and FO separators, to unlock more waste steam, and generate clean power as a result.